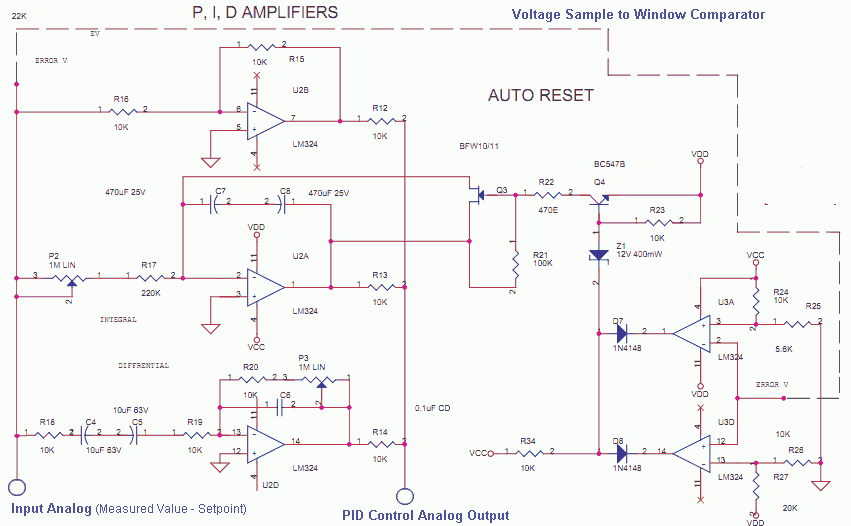

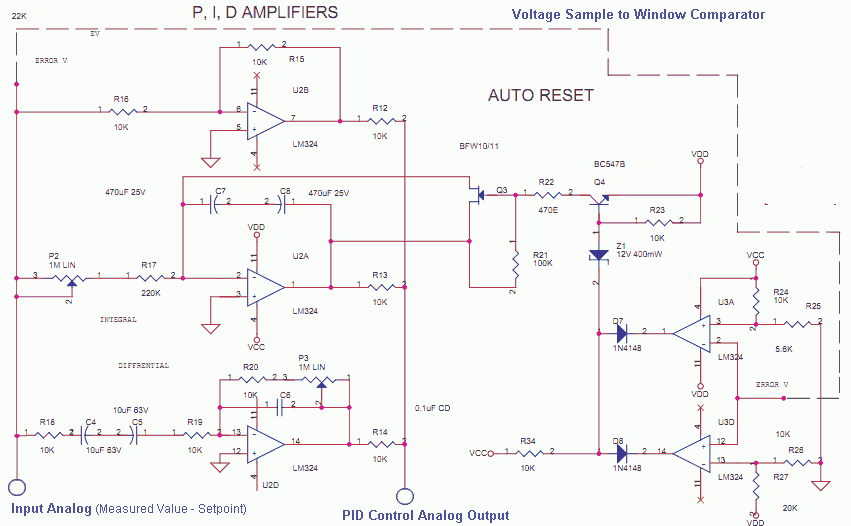

Analog PID control using OpAmps

The Measured Value and The Setpoint are two inputs to a Control System. The Measured Value is the Amplified input of a Transducer or Sensor for some Parameter that needs to be controlled. It could be Pressure or Temperature…etc.

The Setpoint is the User Defined Input using a Potentiometer, Thumbwheel, EPROM or Flash Value. This is the value at which the process has to be maintained for that parameter.

Industrial Process Control Circuits

The difference of these two is the Error, this is the input for this PID Analog Computation Stage. The three Opamps are configured as Proportional, Integrator and Differentiator Amps. The Addition or Summation of these Values is the PID Control Output.(These days it is Math in the Firmware on a MCU, DSP or Software Application in SCADA)

This Analog PID Control Output can now be translated to a 4-20 mA Control Signal, that means 0-100% of power to the Actuator, which could be a Heater, Pump, Fan, Motor using AC/DC Drives. It could be a Steam Valve, Pneumatic or Hydraulic Motorized/Solenoids. The Actuator Size/Array must be right for the Process, a tiny fan cannot cool a Large Furnace, a small solenoid valve cannot fill a Big Tank. An effective Proportional or PID control depends on choosing or designing the Sensor, Actuator and System Environment prudently.

The Auto Reset is needed to ensure the Integrator does not dampen the Process so much that it fails to even raise to the Process value fast enough (Diffrentiator). So in the Proportional Band the Integrator is Active.

If the Setpoint is 1000 deg C, the proportional band is 10%. The Raise of temperature till 950 deg is Undampended. After that Integrator is called in by the Window Comparator made of two opamps, the integrator prevents OverShoot, Undershoot, Ringing and Oscillations.

The PID control output can also be a Time Proportional Output like PWM. With a large cycle time of 20 or More seconds. Like 2 Seconds on and 18 Seconds off for 10% Control.Fast Cycle times may be needed for small systems with less inertia.